|

| 10:00 – 10:30 |

- VINAS’s High-Speed Calculation Technology and Related Services

- Inemi Yamamoto

HPC Solution Management, Sales & Industrial Marketing Department, VINAS Co., Ltd.

- Increasing size and resolution of scientific simulations are posing challenges in speed and accuracy of calculation. In this presentation, an overview of VINAS’s solutions to these bottlenecks will be given.

|

|

| 10:30 – 11:00 |

- Introduction to SMS Products and Parallelization of SMS-AMG

- Akihiro Ida, Ph.D., Technology Research Group, Project Development Department, VINAS Co., Ltd.

- VINAS’s Super Matrix Solver (SMS) can speed-up and stabilize numerical simulation codes. In response to customer requests, we are now developing parallel version of SMS-AMG. This presentation will give an overview of SMS in general and development of the parallel SMS-AMG.

|

|

| 11:00 – 11:45 |

- Special Speech

Electromagnetic Analysis of Superconductivity for Applied Research in Energy and Medical Fields

- Prof. Naoyuki Amemiya

Department of Electrical Engineering, Graduate School of Engineering, Kyoto University

- My current research interests include energy and medical applications of superconductors. Numerical electromagnetic field analysis plays a key role in such research area. In my talk, first, I will present the overviews of two projects, in which I am involved: the R&D of superconducting power transmission cables and the R&D of accelerators for carbon cancer therapy etc. using superconducting magnets. Then, the important role of numerical electromagnetic field analysis using SMS-BEM will be presented.

|

|

| 11:45 – 11:50 |

Break |

| 11:50 – 12:35 |

|

- Special Speech

Strategy for Applying Large-scale Parallel Calculation in Design Process

- Dr. Kenji Ono

Institute of Industrial Science, The University of Tokyo, Researcher

|

|

| Application of large-scale parallel calculation in design process of industrial products necessitates not only improved simulators, but also establishment of clear application strategy addressing related technology such as pre/post processors. This presentation will discuss essential technology and technological trends in design calculations involving large-scale calculation resources such as K Computer as we are entering the age of PFLOPS. |

| 12:35 – 13:55 |

Lunch / Demonstration *Short presentation |

| 13:55 – 14:25 |

- VINAS Product Development and Engineering Service Strategy for Large-Scale Calculation and Cloud Computing

- Kazuya Goto, Technology Research Group, Project Development Department, VINAS Co., Ltd.

- As cloud computing permeates in the field of HPC, support for large-scale calculation is becoming one of the most important key of successful business in this industry. This presentation will provide an overview of VINAS’s service of supporting customers with their large-scale calculation in the latest and future computing environment.

|

|

| 14:25 – 15:10 |

|

- 【Special Speech】

Looking to the Future of Computer Simulations

- Mr. Masahiro Fukuda

Chief Coordinator , Foundation for Computational Science |

|

| It has been almost 40 years since the world’s first supercomputer was built (the term “supercomputer” didn’t even exist at the time). This presentation will take a look at the developments through the years and the current situation of computer simulations, and discuss what’s expected in the future. |

| 15:10 – 15:40 |

|

- Sponsor presentation

Increasing Competitiveness by Using HPC on Cloud

- Mr. Ken Tamagawa

Evangelist, Amazon Data Services Japan

|

|

| Using HPC on the cloud is not anymore a future concept. It is already a feasible practice. This presentation will include advanced examples in the engineering field at NASA and manufacturing industry, some demonstrations, and discussion about new trends of HPC that will add competitiveness. |

| 15:40 – 16:00 |

Coffee Break/Demonstration *Short presentation |

| 16:00 – 16:30 |

- Automation of CFD Pre/Post Processing and its Use in On-demand Cloud Environment

- Kazuhiro Hashiba, Manager, Project Development Department, VINAS Co., Ltd.

- One of the challenges facing large-scale numerical analyses using cloud computing is how to effectively handle analysis results that are in the order of terabytes. This presentation will show examples of automated pre/post processing tools developed by VINAS, and discuss the possibility of using them in the cloud environment.

|

|

| 16:30 – 17:00 |

|

- ASNARO - Next Generation of Simulation Management System

- Mr. Yutaka Ueshima, Ph.D.

Representative director, Quatre i Science Co. Ltd.

|

|

| “Comparing simulation results” sounds easy, but in reality, it is very difficult to know "Where and how results were different", "What kind of processing caused the difference". By solving this issue,the next generation simulation management system aims at reducing work load of engineers and improving quality and throughput of product development work. |

-Please note the program may change without prior notice.

-Company and product names are trademarks or registered trademarks.

![Pre-processor/Aerospace, Turbo-machinery, Other Industries, Design Optimization [II]](img/program_title_day2_01.gif) |

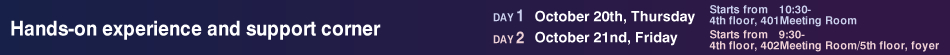

| 9:30 – 9:45 |

- Pointwise V17.0 – Significant Improvement of High-Quality Mesh Generation Functions

- Masanori Hashimoto, Product Group, Engineering Department 1, VINAS Co., Ltd.

- The forthcoming V17.0 of Pointwise comes with all the main features of Gridgen including Native CAD Readers and T-REX, as well as its own new features to make it a whole new, comprehensive mesh generation system capable of robustly generating highly quality mesh. This presentation will provide an overview of high-quality mesh generation and user-friendly operation of Pointwise V17.0.

|

|

| 9:45 – 10:25 |

|

- Efficient, Large-Scale Meshing with Pointwise

- Mr. Richard J. Matus, Ph.D.

Vice President, Pointwise, Inc. |

|

| Engineers are taking advantage of advances in computing power to add fidelity to simulations, resulting in larger and larger meshes. Approaches to efficiently generating and manipulating large-scale grids will be discussed and several examples highlighting these techniques will be presented. |

| 10:25 – 11:05 |

|

- North American Eagle Project – Challenging the Landspeed Record Using Pointwise Software for Aerodynamic Design

- Mr. Darren Grove

Aerospace Engineer, Boeing Commercial Airplanes |

|

| The North American Eagle Project will attempt to take a jet powered car to 800 MPH and bring the record back to North America, currently held by the British since 1997. POINTWISE computational mesh generation software is used to build computational meshes for use in three-dimensional (3D) Navier-Stokes analyses to optimize aerodynamic performance. |

| 11:05 – 11:10 |

Break |

| 11:10 – 11:40 |

|

- Application of Automatic CFD Mesh Generation for Ship Design

- Mr. Tadaaki Kaneko

Ship and Marine Technology Dept., Products Development Center, IHI Corporation |

|

| In the ship design process using the CFD (RANS), computational mesh generation is an essential and critical step. This presentation will show an example of improving efficiency of design process by developing an automatic mesh generation system using Glyph2 function of Pointwise. |

| 11:40 – 12:55 |

Lunch / Demonstration *Short presentation |

| 12:55 – 13:10 |

- Application of CRUNCH CFD V2.4 for Complicated Fluid Phenomena

- Takeru Fukuchi, Ph.D.

General Manager, Engineering Department 2, VINAS Co., Ltd.

- This presentation will introduce main features and newly added functions of high capability and fidelity CFD solver CRUNCH CFD V2.4, as well as its application examples in the areas of turbo-machinery and aerospace with their verification results.

|

|

| 13:10 – 13:50 |

|

- New Developments and Recent Applications of CRUNCH CFD for High-Fidelity CFD Analysis

- Mr. Jai Singh Sachdev, Ph.D.

Research Scientist, Combustion Research and Flow Technology Inc. |

|

| The developmental goal of CRUNCH CFD is to provide advanced capabilities typically not available in other commercial codes. Recent advances will be described through relevant problems in turbo-machinery, scramjets, liquid sprays and droplets, combustion modeling, and moving boundaries. |

| 13:50 – 13:55 |

Break |

| 13:55 – 14:25 |

|

|

- An End-to-End High Fidelity Numerical Simulation of the LE-X Engine

- Achievement by CRUNCH CFD, Gridgen and FieldView -

- Dr. Nobuhiro Yamanishi / Dr. Naoki Tani,

JAXA's Engineering Digital Innovation Center, JAXA |

|

| In JAXA, we tackled the challenges of the world’s first high-fidelity CFD analysis of the whole rocket engine in order to precisely evaluate its performance and risk before conducting the engine test. This presentation will illustrate our use of CRUNCH CFD, Gridgen and FieldView together, which were essential for this world’s first achievement. |

| 14:25 – 14:55 |

|

- Application of CRUNCH CFD to LE-X Engine Development

- Mr. Daiki Watanabe

Design Engineer, Liquid Rocket Engine Design Section, Mitsubishi Heavy Industries, LTD. |

|

| Mitsubishi Heavy Industries (MHI) is engaged in a joint research project of the first-stage engine, “LE-X”, for the Next Flagship Launch System (H-X) with Japan Aerospace Exploration Agency (JAXA). In this activity, a design tool using high fidelity fluid numerical simulation, the CRUNCH CFD, is developed. This presentation will show examples of rocket engine analysis using CRUNCH CFD and prospects for future. |

| 14:55 – 15:15 |

- Increasing the Efficiency of Turbo-machinery CFD Design Process with BladeMaster III and TurboReporter III

- Yoshiyuki Sawa, General Manager, Engineering Department 1, VINAS Co., Ltd.

- BladeMaster III, a Gridgen add-on which automates grid generation of turbomachinery, and TurboReporter III, a FieldView add-on which automates generation of report, robustly support increased accuracy of CFD analyses with the capability of generating high quality mesh independent of the operator's skill and integrated expert know-how in evaluation of turbo-machinery designs. This presentation will illustrate advantages of each of the tools and provide their application examples in design processes.

|

|

| 15:15 – 15:35 |

Coffee Break & Demo *Short presentation |

| 15:35 – 15:50 |

- TURBOdesign Suite 5.0/5.1 – Comprehensive Fluid Dynamic Design Systems for Turbomachinery and Their Benefits

- Yukihiro Yamamoto, Product Group, Engineering Department 1, VINAS Co., Ltd.

- This presentation will provide the latest information regarding TURBOdesign products, including the capability of designing meridional blade shape of centrifugal pumps and compressors, designing and optimizing blades based on 3D inverse design method by TURBOdesign1, and designing volute shapes with a newly added module based on the method applying inverse design.

|

|

| 15:50 – 16:30 |

|

- New Features and functionalities in TURBOdesign Suite for Optimal turbomachinery design

- Prof. Mehrdad Zangeneh

Managing Director, Advanced Design technology Ltd. |

|

| In this presentation, the new features and functionalities of TURBOdesign Suite 5.0 will be shown by reference to various turbomachinery components. |

| 16:30 – 17:00 |

|

- Application of 3D Inverse Design Software TURBODesign1 and CFD in Design Optimization of Cryogenic Pump Inducer

- Mr. Hiroyoshi Watanabe, Dr. Eng.

Group Manager, Fluids Engineering Group, Technology Development Department, Fluid Machinery Development Division, EBARA Corporation Fluid Machinery & Systems Company

|

|

| Design optimization of a pump inducer considering suction performance and cavitation instability was conducted by using TUBOdesign1, CFD, and design of experiment. Streamwise blade loading distribution and outlet vortex design (spanwise loading distribution) were used as design variables. Results will be discussed in this presentation. |

| 17:00 – 17:05 |

Break |

| 17:05 – 17:20 |

- An Overview and the Latest Information of Oofelie Multiphysics V4.3 – Strong-coupling Analysis System for Designers

- Sadahiro Kan, Product Group, Engineering Department 1, VINAS Co., Ltd.

- Developed by Open Engineering in Belgium, Oofelie Multiphysics is a strong-coupling analysis system for designers, supporting wide range of physical fields including structure, thermal, electric and fluid. An overview of the system, new features of the latest version 4.3, as well as future development plans will be given in this presentation.

|

|

| 17:20 – 18:00 |

|

- New Challenges in Multiphysics Simulations.

- Mr. Pascal De Vincenzo

General Manager, Open Engineering S.A.

|

|

| Open Engineering, part of the Samtech group, is a breakthrough supplier of Multiphysics software for the CAE market. The Oofelie::Multiphysics platform, optimized for large complex industrial 3D design work, provides you with unique capabilities to analyze industrial applications such as: sensors & actuators, MEMS & MOEMS and Fluid Structure Interaction problems. |

| 18:00 – 18:15 |

- Closing Speech

- Yasuhiko Fujikawa, President & CEO, VINAS Co., Ltd.

|

-Please note the program may change without prior notice.

-Company and product names are trademarks or registered trademarks.

![]()

![Pre-processor/Aerospace, Turbo-machinery, Other Industries, Design Optimization [II]](img/program_title_day2_01.gif)

![]()